- Home

- Solutions

- Case Studies

- KEYENCE Portable CMM Provides Machine Shop With Rapid Inspection Resource

KEYENCE Portable CMM Provides Machine Shop With Rapid Inspection Resource

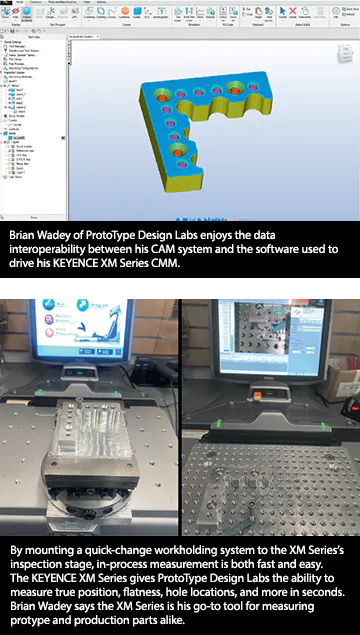

基于西雅图的原型设计实验室 - 快速转机的专家,高混合,低容量加工 - 利用关键XM系列便携式,台式坐标测量机(CMM)的优势进行工艺零件检查和缩短组件客户提供时间。

Brian Wadey, President of Prototype Design Labs, established the company in 2017, following a career as a Senior Prototype Design Engineer and CNC programmer in sectors such as medical, aerospace and education.

Niche opportunity

“我形成了原型设计实验室,为西雅图地区提供了一个不断增长的研究界,这些社区往往努力寻找能够满足他们苛刻要求的机器商店”explains Wadey.“Initially, many of the parts we manufactured were for biology and cell research systems. Since then, however, we’ve added Xometry work into our mix.”

Xometry is a major, US-based marketplace for on-demand industrial prototypes and production parts. Among the keys to being successful, being a Xometry supplier means moving from design to finished component as quickly as possible. Suppliers such as Prototype Design Labs visit a ‘job board’, where Xometry’s algorithm posts jobs based on which partners have the right equipment and experience to complete the work successfully in the required lead time. Partners receive notifications that a new job is available and the first to accept gets the work.

“主要工作wi之前我必须解决的问题th companies such as Xometry was the need for a high-level inspection resource,”says Wadey.“我熟悉传统的CMMS,但我被简单,易于操作,紧凑的脚印和来自Keyence的简单性,易用性,紧凑的足迹和价格。一旦我看到它,我就知道这正是我需要的。“

Simplicity and speed

With no CNC programming and no moving parts, the KEYENCE XM Series is suitable for use by anyone, anywhere in the facility including the shop floor. The XM Series provides the ease of calipers, but the capabilities of a CMM. The XM features a handheld, free-angle probe, to allow measurement from any position. It also boasts on-screen tutorials, temperature compensation, and 3D CAD comparison and export functions. Optical technology enables freedom of approach with touch-to-measure operability. The XM utilizes augmented reality to overlay the 3D image on the probe-mounted camera image, simultaneously displaying measurement information on a live image of the part. This feature allows users without any previous CMM experience to intuitively understand the measurement process.

在加工操作之后,原型设计实验室使用其关键XM系列来进行关键测量,并确定公司数控机床上可能需要调整。此功能增加了显着的价值,因为它允许业务更快地完成零件并实现更快的周转时间。反过来,Wadey可以采取更多的工作,更有效地利用他的生产设备。

“XM提供了许多援助制造和检查的选项,”he states.“这是一个很好的入门级选择,非常易于操作,并随时随地进行自我指导。此外,我们可以为批量生产创建可重复的CMM程序,并使用增强图片生成报告,显示如何完成检查。我们还可以使用其他keyence XM用户共享CMM程序。“

In-process inspection

Wadey说XM非常适合原型设计和过程中的检查。通过使用专用的工具,例如公司的五轴加工中心上的Lang Zeropoint钳位系统,可以在数控机器和关键XM上移动零件,以检查“飞行”。

“XM也从GD&T [几何尺寸和公差]的角度来看,特别是在使用诸如塑料的柔软材料时,可以在加工过程中偏转,”says Wadey.“世界正在朝着型号的定义移动,关键XM具有一个很好的功能,允许导入CAD文件[诸如步骤或IGES]。然后,我们可以对齐坐标系并检查与CAD模型的任何偏差。使用XM的手持式探头,整个过程很容易。我已经在制造业大约35年了,我可以记住零件有时需要几天的时间来通过检查部门。不再。”

Wadey还喜欢XM上没有移动部件,这意味着没有任何磨损。此外,没有年度维护费用。

High confidence levels

“最终,由于关键XM左右到达18个月前,我们在加工工件中拥有的信心已经通过了屋顶,”他说。“In our line of work, it’s all about repeatability. We can use the XM to check a new part/ model, and at the same time, we are building a program that we can use later to check our correction-run components. It’s a form of SPC [statistical process control].”

Beyond the technology, Wadey also has praise for the support from KEYENCE, which never wavered, even during the height of the Covid-19 pandemic, thanks to its online virtual service.

他注意到:“Today, if I need some assistance, I simply send a file and KEYENCE provides advice on how to check a certain feature. You never stop learning, even with all of my experience. The response from KEYENCE is always really quick, often within an hour. I can’t say enough good things about the support they offer.”

APPLICABLE PRODUCT CATALOG

- XM Series Handheld Probe Coordinate Measuring Machine Catalog

-

使用新原理的自由角探头允许通过以任何角度保持的探针进行精确测量,从而能够计算包括热膨胀系数的计算。这是XM系列手持探头坐标测量机的目录,可以导出自由形状曲面的3D CAD数据。ob play

Related Products

-

-

ob play

XM系列

-

ob play